1st shift – LABOUR/CONTRACT

EXPERIMENT

In the various engineering disciplines, less and less use is being made of experiment as a way of developing a concept. This is because computer simulation programmes (basically mathematical models that try to represent our reality) are highly developed and can predict physics with great reliability. A great advantage of simulation programs is that they do not dispense with the construction of real models to test concepts, which are usually expensive and have a much longer production time than a simulation. Nowadays, what type of workspaces and tools are suitable for scientific-technological development?

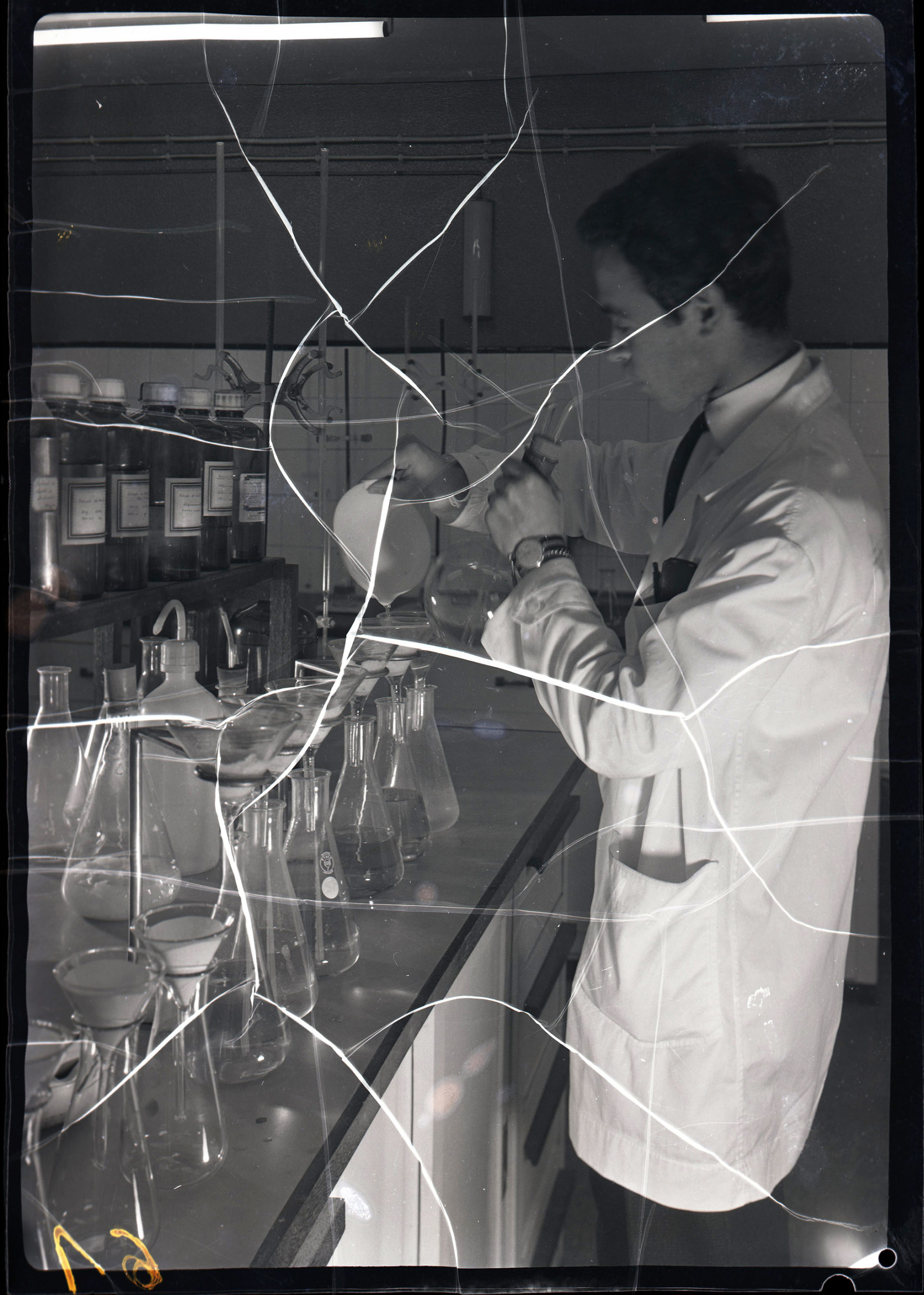

38. Laboratory, ELECTRO PORTUGUESA LDA. 1947-1997. Teófilo Rego Archive, Casa da Imagem – Manuel Leão Foundation, Vila Nova de Gaia, Portugal.

In order to create a computer simulation, characteristics associated with the physical phenomenon in question are required. Usually, these characteristics are obtained through experiments. For example, to find out the strength of a certain material, someone had to pull a specimen to failure, and with the values obtained introduce them in the simulation. Therefore, even for computer simulation programmes, experimentation is essential as a basis and validation. In order to continue developing products such as medicines and cosmetics, will we be able to abandon the use of live animals in experiments or not?

39. Bial, pharmaceutical company. 1947-1997. Teófilo Rego Archive, Casa da Imagem – Manuel Leão Foundation, Vila Nova de Gaia, Portugal.

An experiment is any procedure used to test/demonstrate a method, equipment or technology with a view to innovation. It must reproduce as well as foster the production chain and assembly line through which the product will pass. These experiments – conceptual, aesthetic, functional, ergonomic or mechanical – are associated with industrial research and experimental development. The first is oriented towards the acquisition of new knowledge and the capability of developing new products, processes or services or so as to introduce significant improvements in existing products, processes or services. The latter corresponds to the acquisition, combination, configuration and use of relevant scientific, technological and commercial knowledge and capacities, among others, with the aim of developing new products, processes or services. Industrial research and development corresponds to a school of technological maturity (named by EU the “TRL”) comprising 9 levels, to which the first is equivalent to observed basic principles and the last to an approved system in a serial production environment.

In many industrial sectors, these experiences are financially very valuable and lead to actual inventions. The new inventions, or products, will later on be protected with a patent, a “title” which gives its owner the economic and intellectual right in a given area, and for a limited period of time, a right preventing third parties from producing, using, putting on sale, selling or importing the product protected by the patent and/or process or product obtained directly by the patented process. In return, the owners of the patents are obliged to disclose in detail the entire technical content of the matter protected by the patent, making experiments clear and not allowed for free reproduction.

Experiments have different stages and lead to different levels of concretization. For a new product to reach the market it is necessary to pass a proof of concept / demonstration, this action is associated with the functionality of a prototype. When a client desires to demand a product with certain characteristics, they consult the market by asking the manufacturers/factories to prove/demonstrate that its product meets the desired requirements. For example, when a company wants to demand a big fashion collection, it goes to the market to ask for a demonstration/proof from the suppliers attesting that its textile production is in accordance with the company’s needs.