BUTTONS

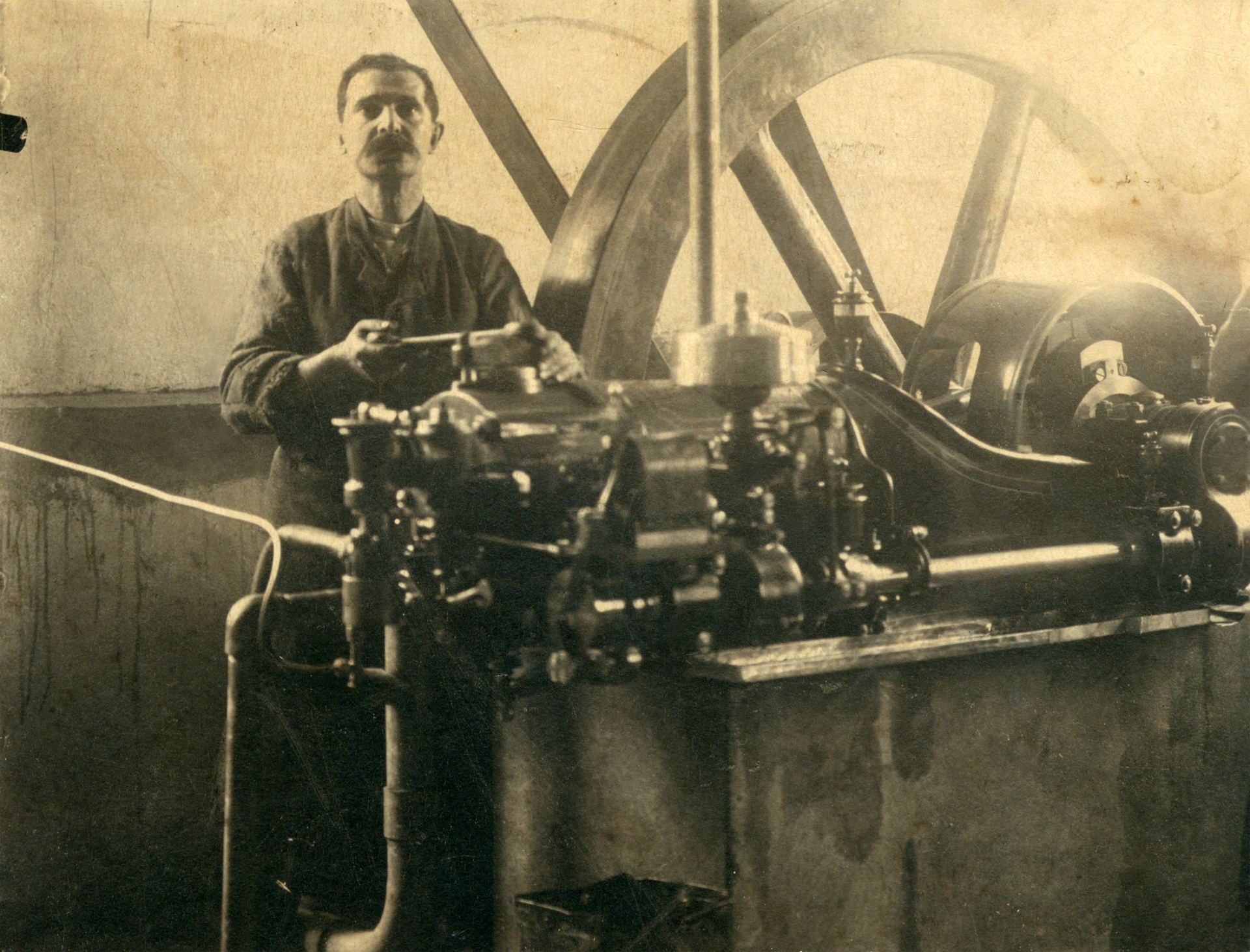

The industrial worker operated devices, pushed cranks, controlling the operation of machines. The machines, once in motion, require the action and full attention of the worker, who is now also controlled by the machine. Nowadays, the automation introduced by digital technologies replaces many of the worker’s previous actions. What is the nature of the current relationship between the worker and the machine in industry? What is the trend in its evolution?

3. Mechanic working the stationary steam machine of one of the old factories. Interactive Museum of Industry, Gabrovo, Bulgaria.

Buttons are often associated with symbols. For example, in the 1960s, to set the tape of a music cassette tape in motion, we pressed a button with a triangle symbol indicating the direction of the tape. The use of the triangle as a “play” symbol became widespread and we now press it to interact with devices whenever we want to watch a video, listen to a song or start a game. What are the symbols we press the most nowadays? Could one of them be the “like” on social networks?

4. Visit to factory premises. CUF (Manufacturing Union Company). 1947-1997. Teófilo Rego Archive, Casa da Imagem – Manuel Leão Foundation, Vila Nova de Gaia, Portugal.

Buttons are objects of different shapes, sizes and materials which, when pressed by a human hand, transform a mechanical movement into an action. The action can be triggered by different impulses, among them the electrical impulse, as is the case of computer keyboards, or the mechanical one, if we consider the case of levers. In particular, the choice of materials for the production of mechanical buttons for industrial tasks can be related to issues related to manufacturing costs, the desired functionality or with the health and safety of workers.

Plenty of industrial mechanisms depend on this interface between human and ma- chine – hence the “Press Here” title – and, therefore, button action programming is essential to numerous functions involving everything from small to large industrial structures. In many cases, the operation safety in machines, industrial buildings, production chains and assembly lines depends on the human decision on a specific button. For example, a person can trigger the fire detection system in a factory through a button and, in that case, the safety of the workers and the raw materials inside this factory may depend on this mechanical push movement.

The end of the buttons may be coming soon, since one of the premises of the current Digital Revolution is to replace the presence of the human being with autonomous processes. Automatization may imply that by removing human presence from part of industrial production, the presence of mechanical buttons will no longer be necessary. On the other hand, digital interfaces such as touch screens have adopted the push movement of fingers, so as to interact with smooth surfaces which don´t have buttons. Press here seems to be an instruction that shifts from mechanical buttons to digital surfaces.